As a supplier of alu honeycomb panels, I've witnessed firsthand the various environmental factors that can influence the performance and longevity of our products. Among these factors, high temperature stands out as a significant concern. In this blog, I'll delve into how high temperatures affect alu honeycomb panels and what you need to know as a potential buyer.

Understanding Alu Honeycomb Panels

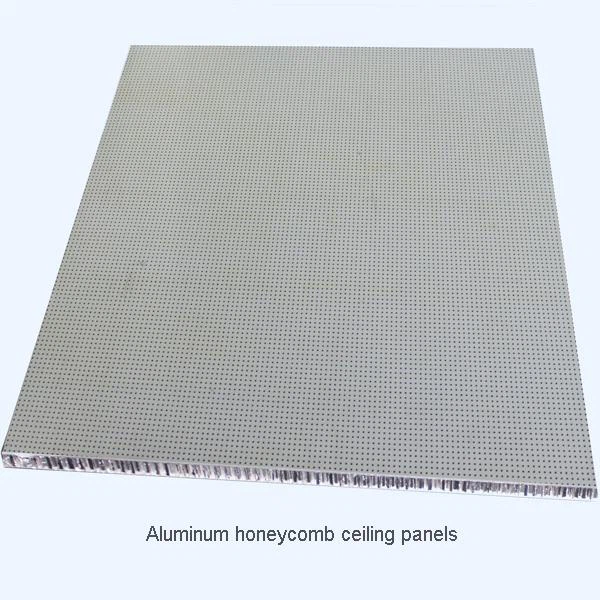

Before we explore the impact of high temperatures, let's briefly understand what alu honeycomb panels are. These panels are composite materials consisting of two thin aluminum sheets bonded to a honeycomb core made of aluminum. This unique structure provides a combination of high strength, lightweight, and excellent flatness, making them suitable for a wide range of applications, including Aluminum Honeycomb Ceiling Panels, Honeycomb Granite Panels, and Perforated Aluminum Honeycomb Panel.

Thermal Expansion

One of the primary effects of high temperatures on alu honeycomb panels is thermal expansion. Like most materials, aluminum expands when heated. The coefficient of thermal expansion for aluminum is relatively high, which means that as the temperature rises, the aluminum sheets and the honeycomb core will expand. This expansion can lead to several issues:

- Dimensional Changes: The overall dimensions of the panel may increase, which can be problematic in applications where precise sizing is required. For example, in architectural installations, even a small increase in panel size can cause fitting problems.

- Stress Buildup: If the panel is constrained in some way, such as being fixed between two rigid structures, the thermal expansion can create internal stress. This stress can lead to warping, bending, or even delamination of the panel.

Bonding Integrity

The bonding between the aluminum sheets and the honeycomb core is crucial for the structural integrity of the panel. High temperatures can have a negative impact on this bonding:

- Weakening of Adhesive: Most alu honeycomb panels are bonded using adhesives. High temperatures can cause the adhesive to soften or degrade, reducing its bonding strength. This can lead to delamination, where the aluminum sheets separate from the honeycomb core.

- Differential Expansion: As mentioned earlier, the aluminum sheets and the honeycomb core expand at different rates due to their different geometries and thicknesses. This differential expansion can put additional stress on the adhesive bond, increasing the risk of failure.

Mechanical Properties

High temperatures can also affect the mechanical properties of the aluminum used in the panels:

- Reduction in Strength: As the temperature rises, the strength of aluminum decreases. This means that the panel may be less able to withstand external loads, such as wind or impact. In extreme cases, the panel may even fail under normal operating conditions.

- Increased Ductility: At high temperatures, aluminum becomes more ductile, which means it can deform more easily. While this may seem like an advantage in some situations, it can also lead to permanent deformation of the panel, reducing its aesthetic appeal and functionality.

Surface Finish

The surface finish of alu honeycomb panels can also be affected by high temperatures:

- Discoloration: Prolonged exposure to high temperatures can cause the surface of the aluminum to discolor. This can be particularly noticeable in panels with a painted or anodized finish.

- Oxidation: High temperatures can accelerate the oxidation process, leading to the formation of a layer of aluminum oxide on the surface of the panel. This oxide layer can be rough and dull, reducing the visual appeal of the panel.

Mitigating the Effects of High Temperatures

While high temperatures can have a significant impact on alu honeycomb panels, there are several ways to mitigate these effects:

- Proper Installation: Ensuring that the panels are installed correctly, with adequate allowances for thermal expansion, can help reduce the risk of stress buildup and delamination.

- Selection of Materials: Choosing high-quality adhesives and aluminum alloys that are more resistant to high temperatures can improve the performance of the panels in hot environments.

- Thermal Insulation: Adding thermal insulation to the panels can help reduce the temperature rise and minimize the effects of thermal expansion.

- Regular Maintenance: Regular inspections and maintenance can help detect any signs of damage or degradation early on, allowing for timely repairs or replacements.

Conclusion

As a supplier of alu honeycomb panels, I understand the importance of providing products that can withstand the challenges of different environments. High temperatures can have a significant impact on the performance and longevity of these panels, but with proper design, installation, and maintenance, these effects can be minimized.

If you're considering using alu honeycomb panels in an application where high temperatures are a concern, I encourage you to contact us to discuss your specific requirements. Our team of experts can help you select the right panels and provide guidance on installation and maintenance to ensure optimal performance.

References

- Callister, W. D., & Rethwisch, D. G. (2017). Materials Science and Engineering: An Introduction. Wiley.

- ASM Handbook Committee. (2000). ASM Handbook Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials. ASM International.